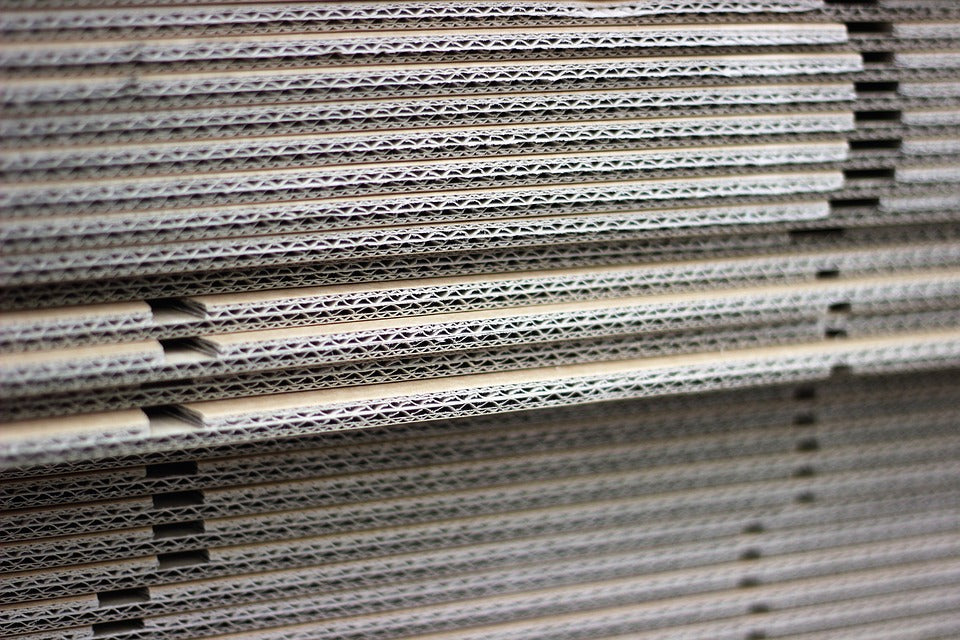

A corrugated board is made up of the two liners, plus the single fluting. This is known as a “single wall” board.

How to Identify Different Board Grades

Corrugated Construction

A standard sheet of corrugated cardboard is made using three components. A sheet of corrugated or “fluted” material in the centre, placed between the outer and inner liners.

Each side of the fluted material is glued to the flat paper liner during manufacture. The glue fixes the flutes in position and adds rigidity and stability to the papers.

Different Types of Paper

There are two types of paper that are generally used for the outer and inner liners. These are known as Kraft and Test liners.

Kraft paper is manufactured from softwood trees. Due to the “virgin” fibers, it is both the strongest type of paper and also the easiest to print on. As a result, it is the most commonly used outside liner when selecting material to produce corrugated boxes and packaging.

Test paper is actually a recycled double sheet of paper. Test paper is not as strong as Kraft, or easy to print on, so is commonly used for the inside liner. It is, however, less costly than Kraft paper.

Wall Types

Additional fluting sections – and additional liners can be added to make what is known as “double wall” or “double walled” material or even triple walled material.

Adding extra rigidity and strength,

Featured Articles

December 03, 2025

Options for Recycling Cardboard Boxes

How to recycle cardboard waste: a guide for business and the home The principles of recycling have b...

November 27, 2025

We are WINNERS of a National Recycling Award!

We're thrilled to announce a big win at the MRW National Recycling Awards 2025! Our pioneering cardb...

October 08, 2025

We’ve been shortlisted for the National Recycling Awards!

We’re excited to announce that we’ve been shortlisted in the circular economy category at the Nation...

July 17, 2025

Sadlers becomes Sustainability West Midlands Member

Back in February this year we made the decision to join the Sustainability West Midlands network whi...